Analytical balances are critical instruments in the fields of scientific research, pharmaceutical development, and quality control. Designed for precision weighing, these balances are capable of detecting minuscule differences in mass, making them essential for any laboratory requiring accurate quantitative analysis. However, the performance of an analytical balance is influenced by several internal and external factors. Understanding and controlling these factors is necessary to achieve optimal accuracy and repeatability.

This article scientifically explores the key variables that affect the performance of an analytical balance and provides guidelines to minimize errors during use.

Environmental Conditions and Their Impact on Analytical Balances

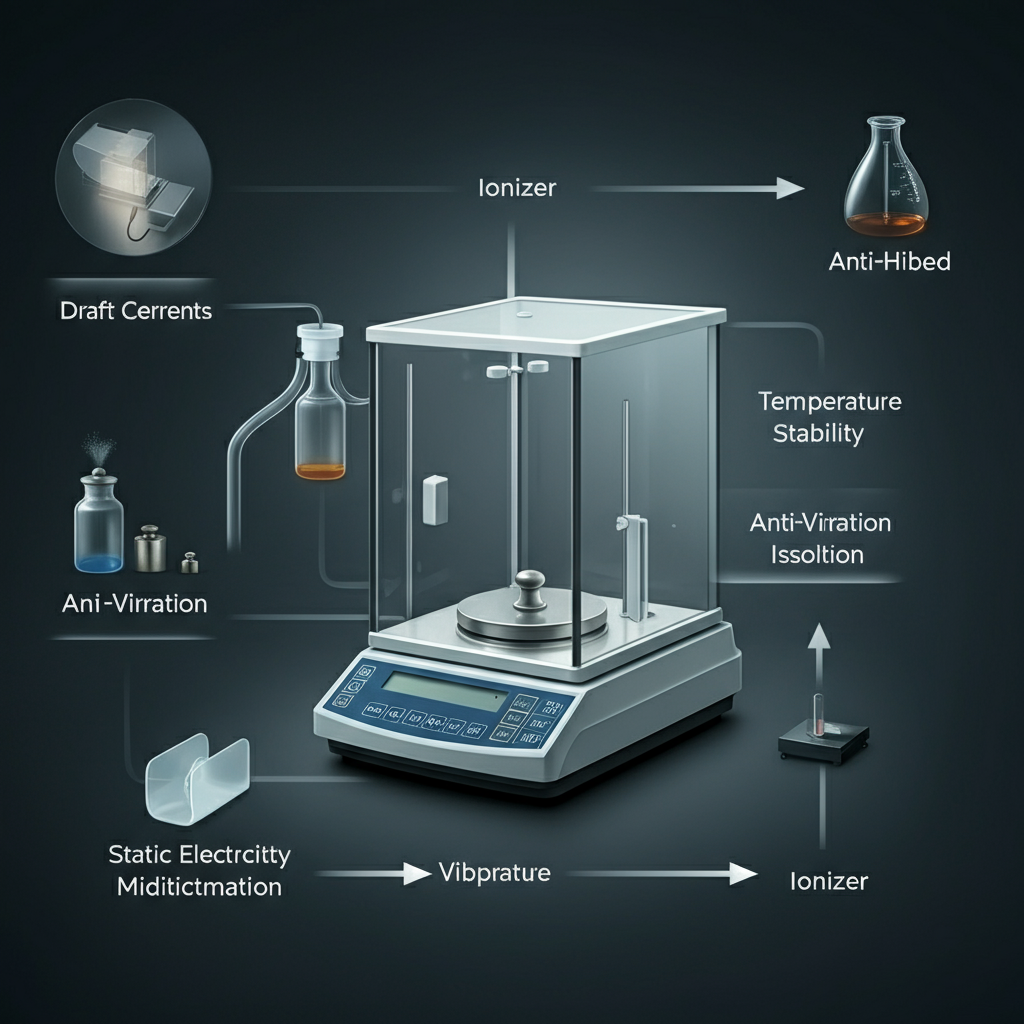

Environmental factors remain one of the most significant determinants of an analytical balance’s performance. These instruments are highly sensitive and can be disrupted by even minor environmental fluctuations.

Air Currents

Even slight air movements, whether from open windows, HVAC systems, or laboratory equipment such as centrifuges, can destabilize the readings of an analytical balance. These disturbances lead to inconsistent results. To mitigate the effect of air currents, balances should be placed in specialized weighing rooms or draft-free enclosures designed to isolate the instrument.

Temperature Stability

Temperature changes have two profound effects on balance operations. First, they can alter the physical dimensions of the balance and its internal components. Second, substances being measured may expand, contract, or lose moisture under varying temperatures. A temperature-controlled environment is advised to maintain balance accuracy. Allow balances and samples to thermally equilibrate to the surrounding environment before use.

Vibration and Disturbances

Vibrations from nearby equipment, foot traffic, or an unstable workbench often reduce measurement accuracy. Analytical balances must be placed on vibration-resistant, firm work surfaces that isolate the instrument from mechanical disturbances.

Humidity Levels

Imbalanced humidity in the laboratory can result in inaccuracies, particularly when dealing with hygroscopic materials that absorb or lose water depending on the surrounding environment. Extreme levels of humidity can also lead to corrosion of sensitive components. Maintaining moderate and stable humidity is recommended for efficiency and precision.

Electrostatic Charges

Electrostatic phenomena, often caused by nearby plastic materials or operator handling, interfere with weighing, especially for lightweight samples. Implementing anti-static systems, such as ionizers or grounding mats, can reduce the influence of static electricity.

The Importance of Calibration

Calibration is fundamental in ensuring that analytical balances deliver precise outputs. Without calibration, both systematic and random errors can accumulate, leading to unreliable data.

Internal Calibration

Most modern analytical balances are equipped with internal calibration systems. These systems automatically readjust the balance settings to compensate for internal drift caused by temperature variations or routine usage. Operating the calibration function before weighing ensures measurement consistency.

External Calibration

For external calibration, standardized calibration weights, certified to national and international standards, are required. Laboratories often follow a strict calibration schedule based on ISO or GLP (Good Laboratory Practice) guidelines. This ensures that the balance remains within acceptable accuracy limits over extended periods.

Maintenance and Cleaning

Proper maintenance routines are paramount for long-term performance and durability. Neglecting maintenance can result in mechanical wear, sensor damage, or contamination, all of which compromise results.

-

Cleaning Procedure: Cleaning the weighing pan after each measurement prevents the accumulation of substances that may alter future readings. Use non-abrasive materials, such as a soft brush or microfiber cloth, to avoid damaging delicate components.

-

Scheduled Inspections: Routine inspections detect wear or malfunctioning parts early. Following the manufacturer’s maintenance guide helps ensure components are functioning optimally.

-

Handling Overloading Issues: Overloading a balance beyond its capacity causes irreparable damage to its sensors. Always adhere to load limits specified in the user manual.

Operator Techniques and Handling

Human error is another significant contributor to analytical balance performance discrepancies. Rigorous training programs for operating personnel reduce the risk of improper handling.

-

Sample Preparation: Samples must be preconditioned to laboratory temperature and humidity to avoid environmental influences. Operators should minimize contact with the weighing pan to avoid accidental contamination or movements.

-

Consistent Technique: Using gloves or tweezers to handle samples precisely and placing the sample slowly on the center of the weighing pan are critical practices to maintain accuracy.

-

Training: Providing laboratory personnel with detailed training on balance operation and best practices ensures that human-induced errors are minimized.

Design and Quality of Analytical Balances

The intrinsic design of a balance greatly influences its ability to deliver consistent and accurate results.

Readability and Sensitivity

Balances with higher sensitivity (e.g., 0.1 mg readability) are typically more accurate for minute measurements but are equally more sensitive to disturbances. Selecting a balance with sensitivity appropriate for the experimental requirements is key.

Advanced Features

Features such as automatic taring, anti-vibration systems, and real-time calibration significantly enhance performance. While these simplify operation, ensuring long-term maintenance of such features is just as important.

Material Composition

Balances made from robust, non-corrosive materials such as stainless steel for the frame and glass for the protective enclosure often display better longevity and durability.

Supplier and Certification

Choosing balances certified by governing institutions, from trusted manufacturers that meet GLP, GMP, or ISO standards, offers assurance of accuracy and functionality.

Sample-Specific Influences

The physicochemical properties of the samples themselves can also alter performance variables.

-

Volatility and Temperature Sensitivity: Samples with highly volatile properties, or those subject to heating/cooling during preparation, may exhibit weight fluctuations. Allow samples to stabilize before measurement for the highest reliability.

-

Moisture Absorption: Hygroscopic substances need quick weighings in controlled humidity levels to ensure mass is unaffected by water-content changes.

Concluding Remarks

Achieving reliable analytical balance performance requires a comprehensive approach to managing external environmental factors, following calibration protocols, and ensuring proper maintenance. High-quality balances, combined with diligent operator practices, lay the foundation for precision weighing in any research or quality control setting.

Laboratories must continually audit their procedures to ensure compliance with best practices. By addressing variables such as temperature, vibrations, operator training, and equipment quality, analytical balances can consistently produce accurate and dependable results for a variety of applications.