Analytical balances are some of the most important tools in the scientific world. Their precision and reliability make them indispensable for researchers, industrial quality control, and advanced laboratories. Despite their widespread use, one question often arises—why are analytical balances so expensive? The answer lies in the complexity of their design, the advanced technologies involved, and the uncompromising standards they are held to. Here, we’ll explore the fascinating science behind these devices and the factors that contribute to their high cost.

1. Precision That Goes Beyond Ordinary Weighing

Analytical balances are engineered to detect minuscule differences in weight—down to micrograms. This level of accuracy far surpasses that of ordinary scales and requires exceptional engineering. Ultra-Sensitive Sensors: The heart of an analytical balance lies in its high-resolution sensors. These are developed using cutting-edge technology to ensure both precision and stability over time. Such sensors can detect even the tiniest changes in weight, making them critical for drug formulation, chemical analysis, and quality assurance in manufacturing. Mitigating External Influences: Analytical balances are designed to counter the effects of external factors, like vibrations, air currents, and even minor temperature changes. Achieving this stability involves intricate mechanisms and finely-tuned components, increasing manufacturing complexity.

2. Advanced Engineering and Manufacturing Processes

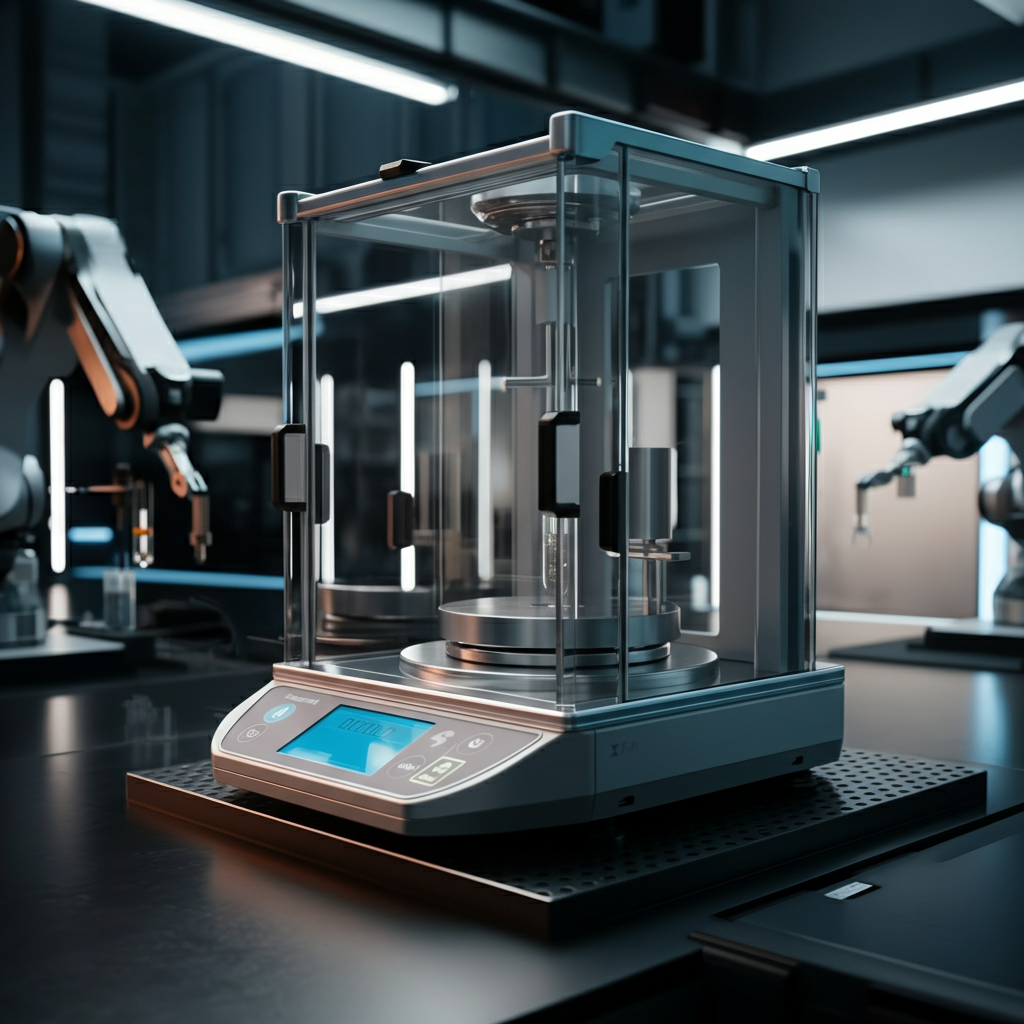

The engineering behind an analytical balance is what sets it apart. These instruments are not simply assembled; rather, every part goes through meticulous design and construction. Draft Shields for Stability: Even air currents from a nearby window can throw off microgram-level measurements. That’s why analytical balances are equipped with draft shields—special enclosures that block external disturbances. These shields are optimized for functionality without interfering with user convenience. Precision Machining: Internal components must align with extreme precision to ensure accurate readings. This requires high-grade manufacturing tools and specialized knowledge, which doesn’t come cheap. Calibration Mechanisms: Most analytical balances include built-in automatic calibration systems. These smart technologies assess and correct measurement errors in real time. While incredibly practical, designing and embedding such systems drives up production costs.

3. Premium Materials for Unmatched Durability

Analytical balances are built with longevity in mind, ensuring they remain accurate even after years of use. To achieve this, manufacturers rely on high-quality materials. Corrosion-Resistant Alloys: Laboratory conditions expose equipment to a range of chemicals. To avoid degradation, analytical balances are crafted from corrosion-resistant metals, such as stainless steel, which can endure harsh environments. Specialized Weighing Pans: The pans used for handling substances must be inert, preventing chemical interactions. Materials like platinum or other high-grade alloys are often employed, adding to the cost. Anti-Vibration Design: An analytical balance may come paired with anti-vibration tables, which further minimize disruptions. These tables use advanced materials and construction processes, contributing to the overall price.

4. Software Integration and Digital Advancements

Modern analytical balances are as technologically advanced as they are mechanically refined. Integrating state-of-the-art software drives up both functionality and production costs. High-Resolution Digital Displays: Balances today are equipped with intuitive, touch-sensitive displays that allow users to seamlessly adjust settings or view data. These aren’t mere display screens—they are optimized for robust use in laboratory environments. Connectivity Features: Many balances today come with USB, Bluetooth, or Wi-Fi capabilities to transfer measurement data directly to computers or cloud databases. This streamlines workflows and enhances productivity in large-scale lab operations. IoT Integration:Some high-end models are designed to work within the Internet of Things (IoT) framework, allowing laboratories to automate processes to save time. Designing and maintaining these advanced software components requires significant investment in research and development.

5. Strict Quality Standards and Testing

Before an analytical balance hits the market, it undergoes rigorous testing to ensure that it meets global quality standards. These checks come at a cost—both in time and resources. ISO & GLP Compliance: Analytical balances must comply with strict standards, such as ISO or Good Laboratory Practice (GLP), which guarantee reliability and precision. High-Level Testing: Manufacturers conduct a wide range of tests on each device, such as repeatability, linearity, and stability tests. Even slight deviations are unacceptable, leading to high rejection rates during quality control. Calibration Certification: Every balance is officially calibrated before shipment, providing proof of its accuracy and reliability. This involves additional testing under varied conditions, further adding to costs.

6. Smaller Market, Higher Per-Unit Cost

The analytical balance market is highly specialized, catering to laboratories and industrial players rather than the general public. This limited demand poses additional challenges. Low Production Volume: Unlike commonly used devices, the production of analytical balances is relatively small-scale. This limits the cost-saving benefits that come with mass manufacturing. Customizations for Niche Industries: Many balances are tailored to meet the specific needs of users in pharmaceuticals, chemical manufacturing, or environmental testing. This customization adds to the design and production expense.

7. True Value Over Time

While the initial purchase price of an analytical balance may seem high, this equipment is a long-term investment. The value it provides over its lifespan far outweighs the upfront cost. Error Prevention: Accurate measurements reduce wastage and prevent errors in research and manufacturing, which could otherwise lead to costly consequences. High Durability: With proper maintenance, an analytical balance can last for decades, earning back its cost many times over. Labor Efficiency: Features like automatic calibration, connectivity, and data analysis save hours of manual labor, streamlining workflows and improving productivity.

Final Thoughts

Analytical balances command a high price because they offer unmatched accuracy, advanced technology, and durability that no other equipment can rival. From the moment they’re manufactured, every step—whether it’s detailed engineering, material sourcing, or rigorous calibration—is geared toward delivering flawless functionality. For professionals in science, industry, or pharmaceuticals who rely on precise measurements, these balances are not just tools—they are essential investments that ensure success in every project. Their high cost is a reflection of their unparalleled ability to deliver accuracy and reliability in even the most demanding environments. It’s a cost well-justified by their impact on modern science and industry.