Analytical balances are fundamental instruments in scientific research and industrial applications, providing the precision necessary for fields such as pharmaceuticals, chemistry, and environmental sciences. These tools facilitate highly detailed measurements, often at the milligram or microgram scale. However, their accuracy and reliability can be significantly compromised by contamination such as dust, residue, or spills. Consistent and methodical cleaning protocols are essential for maintaining their measurement integrity, ensuring equipment longevity, and supporting compliance with stringent regulatory standards.

This article provides a detailed, science-based guideline on how often analytical balances should be cleaned and outlines safe, effective cleaning practices. Recommendations are supported by scientific principles and are tailored to maximize the performance of these precision instruments while minimizing risk of damage.

Importance of Cleaning Analytical Balances

The functionality of analytical balances depends on their ability to deliver precise and reproducible measurements. Cleaning serves as a preventive measure to address potential disruptors of performance. The following points illustrate the criticality of consistent cleaning:

- Prevent Measurement Errors: Contaminants such as dust particles, reagent residue, or liquid spills introduce variability in measurements, directly affecting data accuracy.

- Ensure Regulatory Compliance: Industries like pharmaceuticals and food science are governed by strict quality control standards. Improper maintenance risks non-compliance.

- Extend Instrument Lifespan: Accumulated contaminants can cause internal damage to sensors or load cells, reducing the operational durability of the balance.

- Eliminate Cross-Contamination: Especially crucial in laboratories handling reactive or biohazardous materials, cleaning prevents interaction between successive samples.

Cleaning is not only a practice of routine maintenance but also a safeguard for precision and data integrity in scientific experimentation.

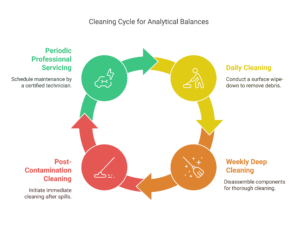

Cleaning Frequency for Analytical Balances

The frequency of cleaning is influenced by the nature and intensity of balance usage in laboratory operations. Adhering to the following cleaning timetable ensures uninterrupted accuracy:

1. Daily Cleaning

Daily cleaning is recommended for balances in heavy-use laboratories where multiple operations occur throughout the day.

- Purpose: Remove accumulations of loose debris and contaminants from routine use.

- Application: At the end of each day or after every weighing session, conduct a surface wipe-down.

2. Weekly Deep Cleaning

Balances should undergo comprehensive cleaning on a weekly basis.

- Purpose: Address hidden residues and ensure the functionality of less-visible components.

- Application: Disassemble removable components (e.g., weighing pan) for thorough cleaning. Clean crevices and fixed parts following manufacturer guidelines.

3. Post-Contamination Rapid Cleaning

Spills, dust clouds, or contact with reactive compounds demand immediate response.

- Purpose: Prevent corrosive or contaminant-induced degradation.

- Application: Initiate cleaning procedures immediately after the spill, using decontamination protocols specific to the substance involved.

4. Periodic Professional Servicing

While routine cleaning is user-conducted, periodic maintenance by a certified technician is beneficial.

- Purpose: Ensure internal components remain unaffected by wear, undetected residue, or misalignment.

- Frequency: Bi-annually or annually, depending on usage intensity and laboratory environment.

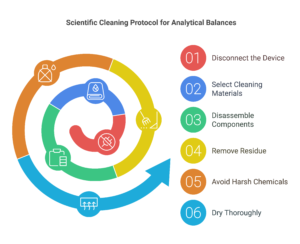

Scientific Cleaning Protocol for Analytical Balances

Cleaning analytical balances requires adherence to scientifically validated procedures. Proper technique not only enhances performance but minimizes risks to safety and equipment integrity.

Step 1. Disconnect the Device

- Turn off the balance and unplug the power cord.

- Scientific Basis: This prevents electrical damage or operator injury during cleaning processes.

Step 2. Select Cleaning Materials

Employ materials compatible with the balance’s sensitive surfaces and components.

- Essential Tools:

- Lint-free, non-abrasive cloths for general cleaning.

- Mild cleaning agents such as 70% ethanol or isopropanol.

- Soft brushes for powdered residue.

- Scientific Basis: Lint-free cloths prevent abrasive wear, while ethanol-based agents effectively sterilize surfaces without introducing harmful residue.

Step 3. Disassemble Components

Remove detachable components, such as the weighing pan, cover, or any trays.

- Scientific Basis: Disassembly permits access to areas susceptible to buildup, ensuring a comprehensive cleaning process.

Step 4. Remove Residue

- Use a brush or compressed air to eliminate loose particles.

- Clean surfaces with a dampened lint-free cloth, paying attention to high-contact areas like the keyboard and display.

- Avoid allowing liquids to penetrate into the internal housing.

- Scientific Basis: Proper surface cleaning reduces obstruction risk to load cells and preserves calibration stability.

Step 5. Avoid Harsh Chemicals

- Use only approved cleaning agents like ethanol or isopropanol. Harsh chemicals like acetone must be avoided as they degrade plastic surfaces and adhesives.

- Scientific Basis: Ethanol’s mild solution is sufficient to dissolve biological or chemical residue without compromising material integrity, whereas acetone introduces compatibility risks.

Step 6. Dry Thoroughly

- Allow washed components to air dry completely. Alternatively, use a disposable, dry lint-free cloth for quicker results.

- Scientific Basis: Complete drying prevents moisture-induced damage to sensors, electronics, or other functional components.

Step 7. Reassemble and Inspect

- Carefully reassemble removable parts, ensuring alignment and structural security. Perform test measurements to confirm functionality.

- Scientific Basis: This step validates that all components were properly cleaned and reassembled for operational efficiency.

Cleaning Agents Selection and Avoidance

The choice of cleaning agents affects the equipment’s durability and accuracy. Use guidelines supported by material science to ensure compatibility with instrument components:

Recommended Agents

- 70% Ethanol or Isopropanol: Offers effective cleaning without attacking plastics or electronics.

- Diluted Detergents: Safe for specific removable components following manufacturer recommendations.

Agents to Avoid

- Acetone: Deteriorates plastic components, seals, and adhesives.

- Strong Acidic or Alkaline Solutions: Harsh chemicals may compromise metallic and synthetic finishes.

Scientific principle determines that low-reactivity solvents (such as ethanol) balance cleaning efficiency with minimal risk to sensitive materials.

Safety Considerations

Adopting robust safety practices during cleaning protects both the operator and the analytical balance. These include:

- Ensure electricity disconnection before handling to mitigate hazards related to power.

- Operate in dust-controlled, well-ventilated areas to reduce contamination during cleaning.

- Utilize manufacturer-approved protocols to address complications or uncertainties.

Such precautions align with occupational safety standards pertinent to laboratory procedures.

Final Recommendations

Maintaining analytical balances involves a scientific approach that emphasizes both scheduled routine and emergency cleaning protocols. Daily cleaning, complemented by weekly deep-cleaning and regular professional inspection, ensures their longevity and accuracy. Employ suitable cleaning agents like 70% ethanol while strictly avoiding abrasive chemicals such as acetone to preserve the material integrity of device components.

By integrating these best practices into laboratory workflows—as guided by scientific principles—you ensure that analytical balances remain precise, reliable, and durable tools in driving scientific advancement.

Implement these protocols today to maintain the integrity of your precision instrument investments while achieving consistently superior operational results.